Modern Agriculture Evolution: The Role of a China Best Tempered Greenhouse Glass Manufacturer in Vertical Farming

QINHUANGDAO, HEBEI, CHINA, January 8, 2026 /EINPresswire.com/ -- The global agricultural landscape is in a phase of rapid transformation, driven by population growth, urbanization, and the pressing need for sustainable food systems. Vertical farming, a method that integrates controlledenvironment agriculture with multilayered crop cultivation, represents one of the leading innovations shaping the future of food production. At the core of this evolution lies the selection of highperformance materials that support plant growth, energy efficiency, and structural stability. Within this context, the presence of a China Best Tempered Greenhouse Glass Manufacturer highlights the importance of advanced glass solutions in modern agriculture, particularly as vertical farming systems seek to maximize light transmission and environmental control.

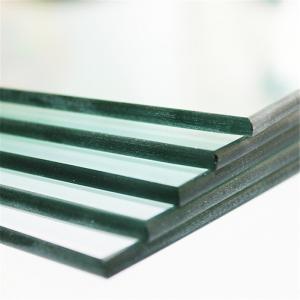

Tempered greenhouse glass is designed to withstand mechanical stress and temperature fluctuations while providing high optical clarity, making it suitable for greenhouse and controlledenvironment applications. Unlike ordinary annealed glass, tempered glass undergoes a specialized heattreatment process that enhances its mechanical strength and safety performance. When integrating glass into vertical farming facilities, attributes such as consistent light transmission, durability, and longterm stability are essential for crop performance and operational efficiency.

The Rise of Vertical Farming and Material Demands

Vertical farming represents a departure from traditional horizontal crop production by stacking growing layers within controlled environments. This approach allows growers to maximize production within limited land areas, reduce dependence on weather conditions, and significantly decrease water consumption compared to conventional agriculture. As this farming model gains traction in urban centers and regions with constrained arable land, material selection becomes pivotal in defining operational outcomes.

Glass plays a central role in vertical farming infrastructure where natural or supplemented light is essential. Transparent or semitransparent glazing materials must deliver high levels of light transmission while maintaining thermal performance and structural resilience. This places specific demands on glazing solutions, particularly tempered greenhouse glass, which must balance optical clarity with physical strength for multitiered installations.

Optical Efficiency and Crop Performance

One of the fundamental requirements in vertical farming is ensuring that sufficient photosynthetically active radiation (PAR) reaches the plant canopy. Light quality, distribution, and intensity directly influence plant growth, nutrient accumulation, and crop yield. Tempered greenhouse glass with high light transmission properties enables growers to capitalize on both natural sunlight and artificial lighting systems, enhancing photosynthetic efficiency.

For example, tempered glass options such as 3mm and 4mm thickness panels are commonly specified for greenhouse applications due to their combination of light transmittance and mechanical rigidity. In vertical farming, where light must penetrate multiple layers of crops and potentially interact with reflective surfaces, consistent optical performance becomes a priority. Thicker tempered glass, such as 4mm toughened panels, offers increased resistance against environmental stressors while still providing reliable light transmission for effective crop photosynthesis.

Similarly, 3mm toughened glass panels present a balance between lightweight construction and sufficient structural support, making them suitable for modular greenhouse frames and specialized vertical racks that utilize daylighting. Horticultural glass variants—such as 3mm horticultural glass—are also used in specific environments where light diffusion and spectrum modulation improve plant growth uniformity.

Structural Integrity and Safety in Controlled Environments

Vertical farming systems often incorporate tall, multilayered structures that demand materials capable of supporting weight and resisting environmental forces. In controlled environments, temperature fluctuations, humidity changes, and automated systems add complexity to structural requirements. Tempered greenhouse glass’s enhanced strength and safety properties reduce the risk of breakage under stress, contributing to reliable longterm operation.

The tempering process increases the mechanical strength of glass, making it more resilient to impact and thermal stress. In greenhouse or vertical farming applications, this strength translates into reduced maintenance and replacement costs over time. The safety performance of tempered glass—breaking into small, blunt fragments rather than sharp shards—also aligns with operational safety protocols in hightraffic agricultural facilities.

LYD GLASS: Supporting Modern Agricultural Applications

LYD GLASS is located in the coastal city of Qinhuangdao in northern China, a region known for its robust glass manufacturing ecosystem. The company benefits from proximity to Qinhuangdao Port and convenient access to Tianjin Port, offering a strategic geographical advantage that supports efficient international transportation and helps reduce logistics costs for global clients.

Within the context of modern agriculture, LYD GLASS supplies a range of tempered greenhouse glass products that align with the demands of controlledenvironment systems, including vertical farming and traditional greenhouses. The company’s portfolio includes 3mm and 4mm toughened glass panels designed for aluminum greenhouse and garden house applications. These tempered panels are engineered for consistent light transmission, structural reliability, and dimensional precision, supporting integration within complex agricultural environments.

In addition to standard tempered glass panels, LYD GLASS provides 3mm horticultural glass tailored for plant growth environments where light diffusion and transformation characteristics are important. Horticultural glass can help manage light distribution within multitiered cultivation areas, reducing hotspots and shadows that might impede uniform crop development.

RealWorld Applications and Client Use Cases

Tempered greenhouse glass supplied by manufacturers such as LYD GLASS has been utilized in a variety of agricultural contexts, from commercial greenhouses to research facilities focused on advanced cultivation methods. In urban vertical farming installations, glass solutions contribute to optimized light utilization while meeting structural and safety criteria.

For commercial greenhouse projects, 4mm toughened glass panels are often specified for roofing and sidewall applications, providing a balance of strength and transparency ideal for expansive glazing systems. These installations benefit from consistent natural light penetration, improved environmental control, and reduced risk of breakage, which cumulatively support stable crop output and operational resilience.

Modular greenhouses and garden house installations typically adopt 3mm toughened panels due to their weight advantages and ease of assembly. When integrated with daylighting systems, these panels support a diverse range of vegetable, herb, and ornamental plant production, particularly in smallerscale or decentralized agricultural deployments.

The use of 3mm horticultural glass further illustrates the tailored approach to specific cultivation strategies. With properties that influence light diffusion, horticultural glass supports environments where uniform illumination is critical—such as propagation rooms, seedling nurseries, and research trial facilities. In these settings, light distribution significantly affects crop uniformity and energy consumption related to supplemental lighting.

Synergy Between Glass Selection and Vertical Farming Technology

Vertical farming often pairs glass or glazing materials with advanced climate control systems, automated LED lighting, and hydroponic or aeroponic infrastructures. The integration of tempered greenhouse glass within these systems contributes to the broader objective of energy optimization, precise environmental control, and plant health.

By ensuring that glass panels deliver consistent optical properties, growers and system integrators can calibrate lighting and environmental systems with greater confidence. This integration reduces variability in plant response and supports scalable production methodologies. In large installations, the ability to predict material performance under diverse conditions helps planners optimize crop schedules and resource use.

Future Directions in Agricultural Glass Applications

The evolution of modern agriculture continues to prioritize methods that increase yield, reduce environmental footprints, and adapt to changing consumer and regulatory landscapes. Vertical farming represents a significant shift toward localized, resourceefficient production, and materials such as tempered greenhouse glass will remain fundamental to this evolution.

As light management technologies advance and controlled environments become more refined, demand for glazing solutions that balance optical clarity, durability, and energy performance will grow. Manufacturers capable of delivering precise, highquality tempered glass products with global distribution capacity are poised to support these emerging agricultural paradigms.

Conclusion

The advancement of vertical farming and other modern agricultural practices underscores the importance of selecting appropriate materials that support plant growth, structural integrity, and operational efficiency. Tempered greenhouse glass offers a combination of high light transmission, mechanical strength, and safety performance that aligns with the demands of controlledenvironment agriculture. As a China Best Tempered Greenhouse Glass Manufacturer, LYD GLASS provides engineered glass solutions that contribute to these evolving farming models, supporting the intersection of material science and agricultural innovation.

For more information, please visit https://www.lydglass.com/.

Tempered greenhouse glass is designed to withstand mechanical stress and temperature fluctuations while providing high optical clarity, making it suitable for greenhouse and controlledenvironment applications. Unlike ordinary annealed glass, tempered glass undergoes a specialized heattreatment process that enhances its mechanical strength and safety performance. When integrating glass into vertical farming facilities, attributes such as consistent light transmission, durability, and longterm stability are essential for crop performance and operational efficiency.

The Rise of Vertical Farming and Material Demands

Vertical farming represents a departure from traditional horizontal crop production by stacking growing layers within controlled environments. This approach allows growers to maximize production within limited land areas, reduce dependence on weather conditions, and significantly decrease water consumption compared to conventional agriculture. As this farming model gains traction in urban centers and regions with constrained arable land, material selection becomes pivotal in defining operational outcomes.

Glass plays a central role in vertical farming infrastructure where natural or supplemented light is essential. Transparent or semitransparent glazing materials must deliver high levels of light transmission while maintaining thermal performance and structural resilience. This places specific demands on glazing solutions, particularly tempered greenhouse glass, which must balance optical clarity with physical strength for multitiered installations.

Optical Efficiency and Crop Performance

One of the fundamental requirements in vertical farming is ensuring that sufficient photosynthetically active radiation (PAR) reaches the plant canopy. Light quality, distribution, and intensity directly influence plant growth, nutrient accumulation, and crop yield. Tempered greenhouse glass with high light transmission properties enables growers to capitalize on both natural sunlight and artificial lighting systems, enhancing photosynthetic efficiency.

For example, tempered glass options such as 3mm and 4mm thickness panels are commonly specified for greenhouse applications due to their combination of light transmittance and mechanical rigidity. In vertical farming, where light must penetrate multiple layers of crops and potentially interact with reflective surfaces, consistent optical performance becomes a priority. Thicker tempered glass, such as 4mm toughened panels, offers increased resistance against environmental stressors while still providing reliable light transmission for effective crop photosynthesis.

Similarly, 3mm toughened glass panels present a balance between lightweight construction and sufficient structural support, making them suitable for modular greenhouse frames and specialized vertical racks that utilize daylighting. Horticultural glass variants—such as 3mm horticultural glass—are also used in specific environments where light diffusion and spectrum modulation improve plant growth uniformity.

Structural Integrity and Safety in Controlled Environments

Vertical farming systems often incorporate tall, multilayered structures that demand materials capable of supporting weight and resisting environmental forces. In controlled environments, temperature fluctuations, humidity changes, and automated systems add complexity to structural requirements. Tempered greenhouse glass’s enhanced strength and safety properties reduce the risk of breakage under stress, contributing to reliable longterm operation.

The tempering process increases the mechanical strength of glass, making it more resilient to impact and thermal stress. In greenhouse or vertical farming applications, this strength translates into reduced maintenance and replacement costs over time. The safety performance of tempered glass—breaking into small, blunt fragments rather than sharp shards—also aligns with operational safety protocols in hightraffic agricultural facilities.

LYD GLASS: Supporting Modern Agricultural Applications

LYD GLASS is located in the coastal city of Qinhuangdao in northern China, a region known for its robust glass manufacturing ecosystem. The company benefits from proximity to Qinhuangdao Port and convenient access to Tianjin Port, offering a strategic geographical advantage that supports efficient international transportation and helps reduce logistics costs for global clients.

Within the context of modern agriculture, LYD GLASS supplies a range of tempered greenhouse glass products that align with the demands of controlledenvironment systems, including vertical farming and traditional greenhouses. The company’s portfolio includes 3mm and 4mm toughened glass panels designed for aluminum greenhouse and garden house applications. These tempered panels are engineered for consistent light transmission, structural reliability, and dimensional precision, supporting integration within complex agricultural environments.

In addition to standard tempered glass panels, LYD GLASS provides 3mm horticultural glass tailored for plant growth environments where light diffusion and transformation characteristics are important. Horticultural glass can help manage light distribution within multitiered cultivation areas, reducing hotspots and shadows that might impede uniform crop development.

RealWorld Applications and Client Use Cases

Tempered greenhouse glass supplied by manufacturers such as LYD GLASS has been utilized in a variety of agricultural contexts, from commercial greenhouses to research facilities focused on advanced cultivation methods. In urban vertical farming installations, glass solutions contribute to optimized light utilization while meeting structural and safety criteria.

For commercial greenhouse projects, 4mm toughened glass panels are often specified for roofing and sidewall applications, providing a balance of strength and transparency ideal for expansive glazing systems. These installations benefit from consistent natural light penetration, improved environmental control, and reduced risk of breakage, which cumulatively support stable crop output and operational resilience.

Modular greenhouses and garden house installations typically adopt 3mm toughened panels due to their weight advantages and ease of assembly. When integrated with daylighting systems, these panels support a diverse range of vegetable, herb, and ornamental plant production, particularly in smallerscale or decentralized agricultural deployments.

The use of 3mm horticultural glass further illustrates the tailored approach to specific cultivation strategies. With properties that influence light diffusion, horticultural glass supports environments where uniform illumination is critical—such as propagation rooms, seedling nurseries, and research trial facilities. In these settings, light distribution significantly affects crop uniformity and energy consumption related to supplemental lighting.

Synergy Between Glass Selection and Vertical Farming Technology

Vertical farming often pairs glass or glazing materials with advanced climate control systems, automated LED lighting, and hydroponic or aeroponic infrastructures. The integration of tempered greenhouse glass within these systems contributes to the broader objective of energy optimization, precise environmental control, and plant health.

By ensuring that glass panels deliver consistent optical properties, growers and system integrators can calibrate lighting and environmental systems with greater confidence. This integration reduces variability in plant response and supports scalable production methodologies. In large installations, the ability to predict material performance under diverse conditions helps planners optimize crop schedules and resource use.

Future Directions in Agricultural Glass Applications

The evolution of modern agriculture continues to prioritize methods that increase yield, reduce environmental footprints, and adapt to changing consumer and regulatory landscapes. Vertical farming represents a significant shift toward localized, resourceefficient production, and materials such as tempered greenhouse glass will remain fundamental to this evolution.

As light management technologies advance and controlled environments become more refined, demand for glazing solutions that balance optical clarity, durability, and energy performance will grow. Manufacturers capable of delivering precise, highquality tempered glass products with global distribution capacity are poised to support these emerging agricultural paradigms.

Conclusion

The advancement of vertical farming and other modern agricultural practices underscores the importance of selecting appropriate materials that support plant growth, structural integrity, and operational efficiency. Tempered greenhouse glass offers a combination of high light transmission, mechanical strength, and safety performance that aligns with the demands of controlledenvironment agriculture. As a China Best Tempered Greenhouse Glass Manufacturer, LYD GLASS provides engineered glass solutions that contribute to these evolving farming models, supporting the intersection of material science and agricultural innovation.

For more information, please visit https://www.lydglass.com/.

QinHuangDao LianYiDing Glass CO.,LTD

QinHuangDao LianYiDing Glass CO.,LTD

+ +86 13315367306

info@dingsen-industry.com

Visit us on social media:

Instagram

X

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.